What’s the difference between pneumatic and hydraulic?

When it comes to fluid power applications, the difference between hydraulics and pneumatics is a common conversation topic.

Pneumatics and hydraulics are used across many different industrial applications, due to their ability to generate substantial amounts of power for a relatively low cost. Whilst both are forms of fluid power technology and have many similarities, their capabilities vary greatly.

When looking at each method, it’s never been a case of which one is better, as they both have pros and cons which make them more or less suitable for specific applications. Understanding the key differences between the two is what will help you decide which type of system you need.

In this article, we’ll provide an overview of both pneumatics and hydraulics, and explore the key differentiating factors between them.

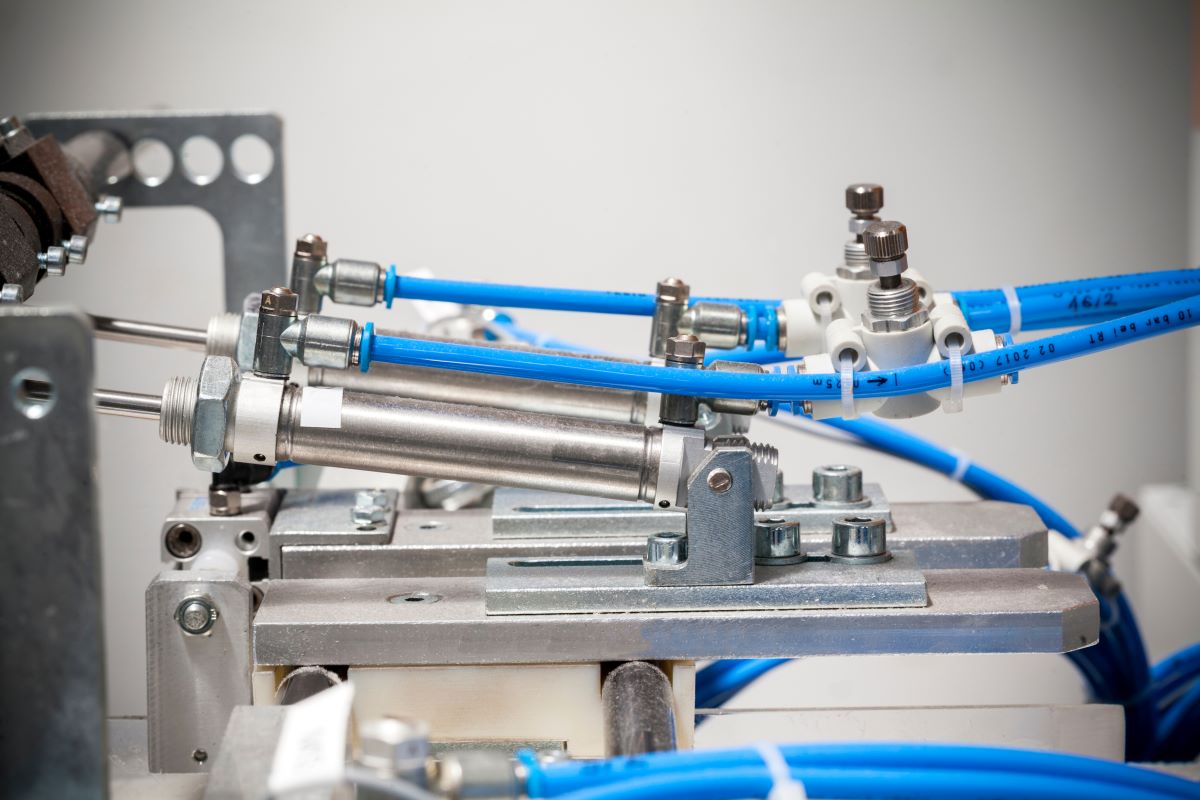

What is pneumatics?

Pneumatics uses pressurised gas or air to produce mechanical energy. Using the physics of fluid power, pneumatic systems will compress a gas or air substance to generate enough energy to move something – such as a cylinder, motor or other mechanical part.

The main components that make up a pneumatic system are:

- A compressor which supplies the air and transmits it through a series of hoses

- A reservoir which stores the air under pressure

- Valves which regulate the air flow

- A cylinder which converts the energy provided to mechanical energy and moves or lifts the object

Pros and cons of pneumatics

Here are some of the key advantages and disadvantages of pneumatic systems in comparison to hydraulics:

Cost

In general, pneumatic systems are cheaper to operate than hydraulic systems, as they rely on air as their main source – which is free, in abundance and easy to replenish. However, pneumatics typically lose more energy through the air compression process, making them less energy efficient.

Safety

Pneumatic systems are considered safer than hydraulics, since air doesn’t present as many dangers as hydraulic fluids. Naturally, air is non-flammable and any leakages are unlikely to pose a risk of danger.

However, pneumatics aren’t completely risk-free. Systems are installed with pipes that have the ability to move freely and uncontrollably, which may cause injuries to operators in certain circumstances. Similarly, some pneumatic systems may use hazardous chemicals within their design.

Cleanliness

Pneumatic systems are often used in environments where cleanliness and hygiene are a priority – such as pharmaceuticals, food suppliers and dentistry. This is because they use clean, dry, compressed air which constantly pushes out any dirt or debris that may get stuck.

Maintenance

Similarly, pneumatic systems are very easy to maintain and have longer operating lives because they are simple in design and the equipment is less susceptible to shock damage.

Size

As pneumatic systems aren’t as complex as hydraulics, they are typically smaller in size and are often portable, providing greater flexibility in application types.

Force

One of the key disadvantages of pneumatic systems is that they can’t generate as much force as hydraulic systems can. Therefore, they aren’t suitable for applications which require moving or lifting heavy loads.

However, pneumatic systems have the advantage of speed as air has a higher potential flow rate than liquid. This means that pneumatics can work at a faster rate, making them more suitable for applications requiring high speed movement.

Key applications for pneumatic systems

Pneumatics are used in various applications across a wide number of industries, such as:

- Air compressors

- HVAC control systems

- Conveyor systems

- Pressure sensors

- Vacuum pumps

- Precision drills and nail guns

- Assembly and manufacturing lines

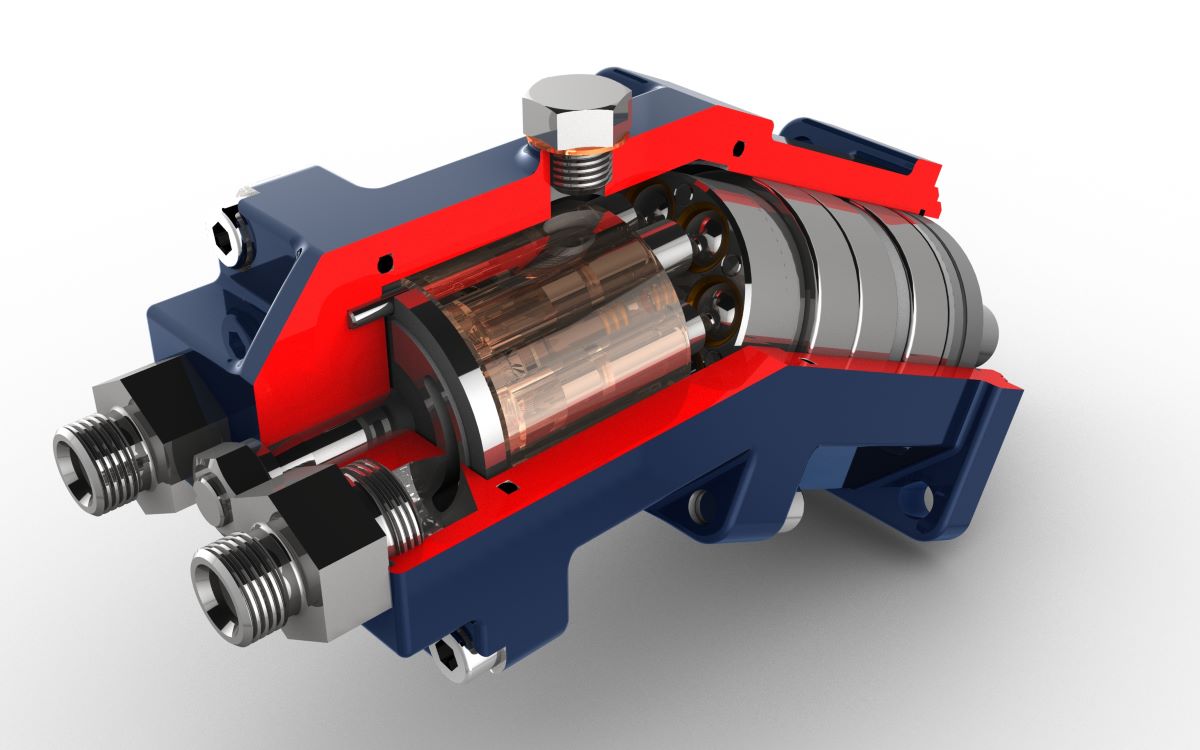

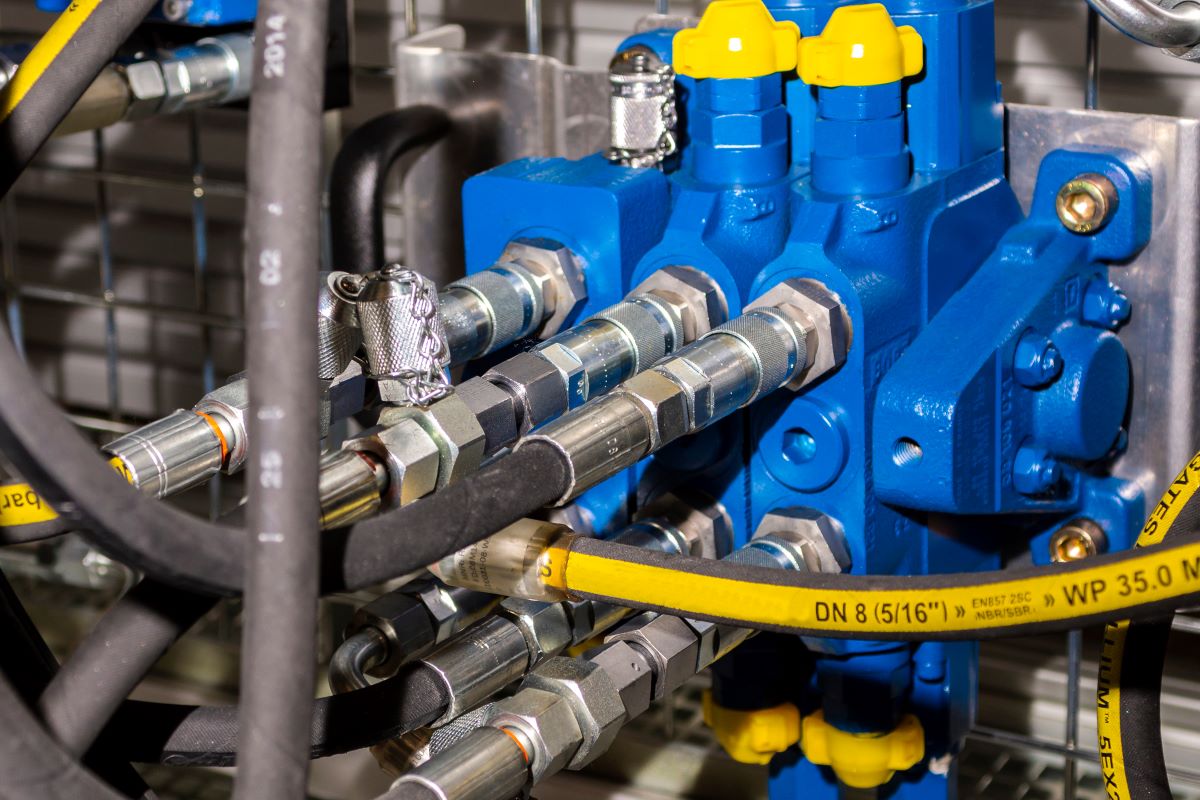

What is hydraulics?

Hydraulics uses the same method of generating, controlling and transmitting power as pneumatics, except it uses pressurised liquids as opposed to gas or air. This is the key difference between the two technologies.

Hydraulic systems comprise the following key components:

- A reservoir to hold the hydraulic fluid

- A hydraulic pump to transmit mechanical energy into hydraulic energy

- Valves to start, stop and direct fluid flow

- A hydraulic cylinder or motor to convert the energy into mechanical energy

Pros and cons of hydraulics

Here are some of the key advantages and disadvantages of hydraulic systems in comparison to pneumatics:

Force

As mentioned previously, hydraulics are more capable of generating higher amounts of force and moving much heavier loads, due to the incompressibility of liquids. Machines powered by hydraulics can operate at much higher pressures (up to 10,000 psi) which makes them a more suitable choice for heavy-duty industrial machinery.

Complexity

Hydraulic systems are much larger and more complex than pneumatics. The equipment is typically more expensive and requires more regular preventative maintenance.

Control

Whilst hydraulic systems are complex in design and engineering, they are easy to control with a great deal of accuracy. Users can simply use a button or a lever and the system will perform whatever action is required.

Safety

When correct maintenance is carried out, hydraulic systems are safely operated but they do pose a number of dangers. Hydraulic fluid is highly flammable and held at extremely high temperatures, which causes major health and safety hazards if a leak was to occur.

Key applications for hydraulic systems

Hydraulics can be found in many every day applications and heavy duty industrial machinery, including:

- Machine tools

- Excavators and cranes

- Theme park rides

- Lifts

- Car braking systems

- Wind turbines

- Mechanical chairs

In summary, pneumatic and hydraulic systems both have their qualities and drawbacks, but this depends entirely on the application in which they are intended for.

We hope you found this article useful, and if you’re looking for any assistance with your hydraulic solution, Primary Fluid Power can help. As one of the UK’s leading hydraulic component suppliers, we can supply an extensive range of equipment from industry-leading manufacturers, and offer advice on the most suitable solution for you.

Browse our products or get in touch with us to make an enquiry.